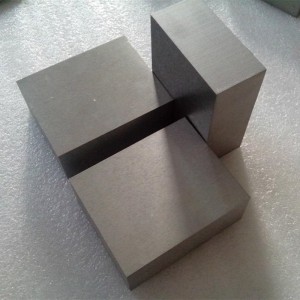

Silver Tungsten Alloy

Sirivha tungsten alloy isanganiswa inoshamisa yesimbi mbiri dzinoshamisa, sirivheri uye tungsten, iyo inopa yakasarudzika seti yezvivakwa uye mashandisirwo.

Iyo alloy inosanganisa yakanakisa magetsi conductivity yesirivheri nenzvimbo yakakwira yekunyungudika, kuoma, uye kupfeka kuramba kwe tungsten. Izvi zvinoita kuti ive yakakodzera kwazvo kune dzakasiyana siyana dzinoda maapplication muminda yemagetsi nemakanika.

Muindasitiri yemagetsi, sirivheri tungsten alloy inoshandiswa mumagetsi emagetsi uye switch. Kugona kwayo kumira tembiricha yakakwira uye arcing inoita kuti ivimbike mune izvi zvakakosha zvikamu. Semuenzaniso, mumagetsi emagetsi emagetsi, uko kuyerera kwezvino kwakakosha uye njodzi yekupisa yakanyanya, kushandiswa kwesirivha tungsten alloy kunovimbisa kushanda kwakanaka uye kwakachengeteka.

Munzvimbo yemakanika, inowana kushandiswa mumaturusi uye inofa nekuda kwekuoma kwayo uye kusimba. Zvikamu zvinogadzirwa kubva kune iyi alloy zvinogona kumira zvakanyanya kushushikana kwemechani uye abrasive kupfeka, kurebesa hupenyu hwavo uye nekuvandudza mashandiro.

Kugadzirwa kwesirivha tungsten alloy kazhinji kunosanganisira maitiro akaomarara kuti uwane inodiwa kuumbwa uye microstructure. Izvi zvinogonesa chiyero chakakwana chezvivakwa kune chaiwo maapplication.

Tsvagiridzo uye kusimudzira mumunda wesirivheri tungsten alloys inoramba ichishanduka, ichivhura mikana mitsva nekuvandudzwa. Masayendisiti uye mainjiniya vanogara vachitsvaga nzira dzekusimudzira zvivakwa zvayo uye kuwedzera huwandu hwekushandisa kwayo.

Mukupedzisa, sirivheri tungsten alloy inomira sechiratidzo chehungwaru hwevanhu mune zvesainzi, ichipa mhinduro kune mamwe ematambudziko akaomarara einjiniya uye tekinoroji. Kusanganiswa kwayo kwakasarudzika kwezvivakwa kunoita kuti ive chinhu chakakosha mumaindasitiri akasiyana, kuumba nyika yazvino nekuvapo kwayo uye kugona.

Kugadzirwa kwesirivha tungsten alloy:

Powder Metallurgy:

Iyi inzira yakajairika. Fine poda dzesirivha uye tungsten dzakasanganiswa muzvikamu zvinodiwa. Musanganiswa wacho unobva wabatanidzwa pasi pekumanikidzwa kukuru kuti uite chidimbu chegirini. Iyi compact inozonyudzwa patembiricha yepamusoro kuti isanganise zvimedu pamwechete uye kugadzira alloy yakasimba. Semuyenzaniso, mune dzimwe nguva, hupfu hunogona kugayiwa pamwe chete kuti ive nechokwadi chekusanganiswa kwehomogeneous.

Chemical Vapor Deposition (CVD):

Nenzira iyi, gasious precursors ine sirivheri uye tungsten inounzwa mukamuri yekuita. Pasi pemamiriro ezvinhu chaiwo ekushisa uye kumanikidzwa, maprecursors anoita uye anoisa pane substrate kuti agadzire alloy layer. Iyi nzira inobvumira kunyatso kudzora kweiyo alloy kuumbwa uye microstructure.

Electroplating:

Sirivha tungsten alloy inogonawo kugadzirwa kuburikidza ne electroplating. A tungsten substrate inonyudzwa mu electrolyte ine sirivheri ions. Nekushandisa magetsi emagetsi, sirivha inoiswa pane tungsten pamusoro, ichigadzira alloy layer. Iyi nzira inogona kugadziridzwa kuti iwane ukobvu hwakasiyana uye maumbirwo eiyo alloy coating.

Sinter-HIP (Hot Isostatic Pressing):

Musanganiswa wehupfu unotanga kunyungudutswa uye wozoiswa pasi pekupisa isostatic kudzvanya. Izvi zvinobatsira kubvisa porosity uye kuvandudza density uye mechanical zvinhu zveyakagadzirwa alloy.

Sarudzo yekugadzira nzira yekugadzira inoenderana nezvinhu zvakasiyana senge inodiwa zvivakwa zvekupedzisira alloy, chimiro uye saizi yechikamu chinogadzirwa, uye chiyero chekugadzira. Imwe neimwe nzira ine zvayakanakira uye zvinogumira, uye kazhinji, musanganiswa weaya matekiniki anogona kushandiswa kuwana mhedzisiro yakanaka.

Silver tungsten alloy ine akati wandei maapplication nekuda kweayo akasiyana zvivakwa:

Zvemagetsi Contacts:

● Mu-high-voltage circuit breakers, kwainokwanisa kubata mafungu makuru uye kuchinja nguva dzose pasina kunyanya kusakara kana kuora.

● In relays uye contactors kuti maindasitiri kudzora hurongwa, kupa yakavimbika magetsi kubatana uye refu basa upenyu.

Electrodes:

● Nezvemagetsi ekubudisa machining (EDM), apo maitiro ayo akakwirira uye kuramba kupfeka kunovimbisa kubviswa kwakanyatsonaka uye kwakanaka.

● Mune arc welding electrodes, inopa zvakanaka kupisa kupisa uye kusimba.

Aerospace Components:

● Muzvikamu zveinjini dzendege uye masisitimu ezvitundumuseremusere zvinoda zvinhu zvine kushivirira kwepamusoro uye simba remagetsi.

Thermal Management:

● Sezvo kupisa kunonyura mumidziyo yemagetsi, kunyatsoita uye kubvisa kupisa.

Kushandisa uye Kufa:

● Pakuita zvitambi uye kugadzira maoparesheni, kunyanya mumashandisirwo apo kuoma kwakanyanya uye kusapfeka kwakakosha.

Zvishongo:

● Nekuda kwekutaridzika kwayo kukwezva uye kusimba, inogona kushandiswa mukugadzira zvidimbu zvezvishongo zvehunyanzvi.

Semuyenzaniso, muindasitiri yemotokari, sirivheri tungsten alloy anobatika anoshandiswa mumatanho emota kuti ave nechokwadi chekuvimbika kutanga kweinjini pasi pemamiriro akasiyana. Mumunda wekufonera, inoshandiswa mu-high-frequency switches kuchengetedza chiratidzo chekuvimbika uye kuderedza kurasikirwa kwechiratidzo.

Silver Tungsten Alloy Properties

| Kodhi Nha. | Kuumbwa Kwemakemikari% | Mechanical properties | ||||||

| Ag | Kusachena≤ | W | Density (g/cm3 ) ≥ | Kuoma HB ≥ | RES (μΩ·cm) ≤ | Conductivity IACS/ % ≥ | TRS/ Mpa ≥ | |

| AgW(30) | 70±1.5 | 0.5 | Balance | 11.75 | 75 | 2.3 | 75 | |

| AgW(40) | 60±1.5 | 0.5 | Balance | 12.40 | 85 | 2.6 | 66 | |

| AgW(50) | 50±1.5 | 0.5 | Balance | 13.15 | 105 | 3.0 | 57 | |

| AgW(55) | 45±2.0 | 0.5 | Balance | 13.55 | 115 | 3.2 | 54 | |

| AgW(60) | 40±2.0 | 0.5 | Balance | 14.00 | 125 | 3.4 | 51 | |

| AgW(65) | 35±2.0 | 0.5 | Balance | 14.50 | 135 | 3.6 | 48 | |

| AgW(70) | 30±2.0 | 0.5 | Balance | 14.90 | 150 | 3.8 | 45 | 657 |

| AgW(75) | 25±2.0 | 0.5 | Balance | 15.40 | 165 | 4.2 | 41 | 686 |

| AgW(80) | 20±2.0 | 0.5 | Balance | 16.10 | 180 | 4.6 | 37 | 726 |