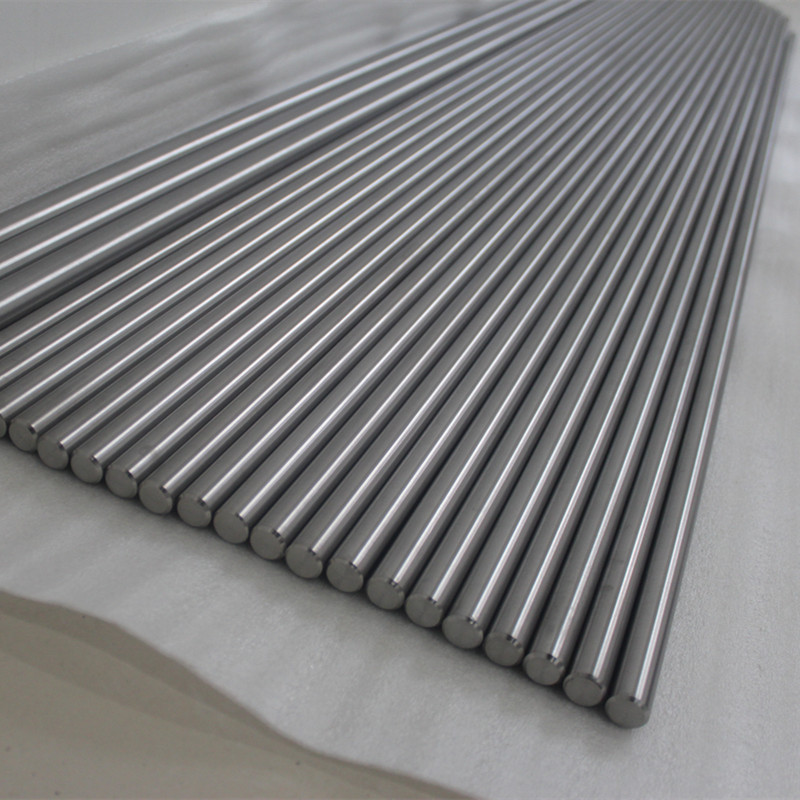

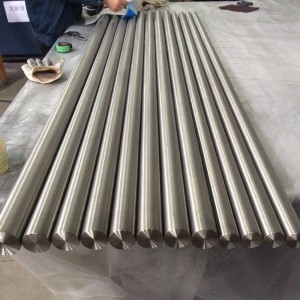

Yakachena Titanium Rod Titanium Alloy Bar

Tsanangudzo

Titanium tsvimbo ndiyo mbishi inoshandiswa kugadzira titanium alloy uye titanium simbi. Iyo ine maitiro ehushoma density, yakakwirira simba uye yakanaka corrosion resistance. Muindasitiri yezvemuchadenga, titanium tsvimbo inoshandiswa zvakanyanya mukugadzirwa kwezvikamu zvechimiro chendege uye maroketi nozzles; muindasitiri yemakemikari, inoshandiswa sechinhu chinotakura uye mudziyo wekuchenesa we electrolytes; muindasitiri yemuchina, inogona kushandiswa sechinhu chinopisa kupisa uye condenser zvinhu.

Muindasitiri yemetallurgical, titanium rod/bar inonyanya kushandiswa kugadzira simbi yakasiyana-siyana yakachena, simbi isina tsvina, simbi inodzivirira kupisa uye yakakosha alloy simbi. Pamusoro pezvo, inoshandiswawo mukugadzira matombo anokosha ekugadzira uye artificial rutile zircon crystals, piezoelectric ceramic sheets eindasitiri yemagetsi, uye nekukandwa chaiko kwemhando dzakasiyana.

Yakachena Titanium Rod / Titanium Alloy Bar Madiro

Titanium Alloy Giredhi:Gr.5, Gr.23, Ti-6Al-4v-Eli, TI5, BT6,Ti-6al-7Nb.

Commercial yakachena Titanium Giredhi:Gr.3, Gr.4 zvekutengesa zvakachena.

Diameter Range:Ø5mm, Ø6mm, Ø8mm, Ø12mm, Ø14mm, Ø25mm, Ø30mm, nezvimwewo.

Tolerance Standard:ISO 286.

Standard:ASTM F67, ASTM F136, ISO 5832.

Hurefu huripo:2.5 m ~ 3 m (98.4 ~ 118.1"), kana yakagadzirirwa.

Kururama:yakakwana kune CNC machining.

Ese maTitanium neTitanium Alloy tsvimbo/mabhawa aigona kupihwa ane dhayamita yakagadziridzwa kana kureba, kuti ikwane zvinodiwa neMutengi.

Zvinoumba titanium alloy tsvimbo:Yakanakisa elasticity, yakakwirira simba uye homogeneous microstructure.

Titanium Giredhi Inowanikwa

| ASTM B265 | GB/T 3620.1 | JIS H4600 | Zvemukati (wt%) | ||||||

| N,Max | C,Max | H,Max | Fe, Max | O,Max | Vamwe | ||||

| PureTitanium | Gr.1 | TA1 | Kirasi 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | - |

| Gr.2 | TA2 | Kirasi 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | - | |

| Gr.3 | TA3 | Kirasi 3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | - | |

| Gr.4 | TA4 | Kirasi 4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | - | |

| TitaniumAlloy | Gr.5 | TC4Ti-6Al-4V | Kirasi 60 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | Al:5.5-6.75;V:3.5-4.5 |

| Gr.7 | TA9 | Kirasi 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | Pd:0.12-0.25 | |

| Gr.11 | TA9-1 | Kirasi 11 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Pd:0.12-0.25 | |

| Gr.23 | TC4 ELI | Kirasi 60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | Al:5.5-6.5;V:3.5-4.5 | |