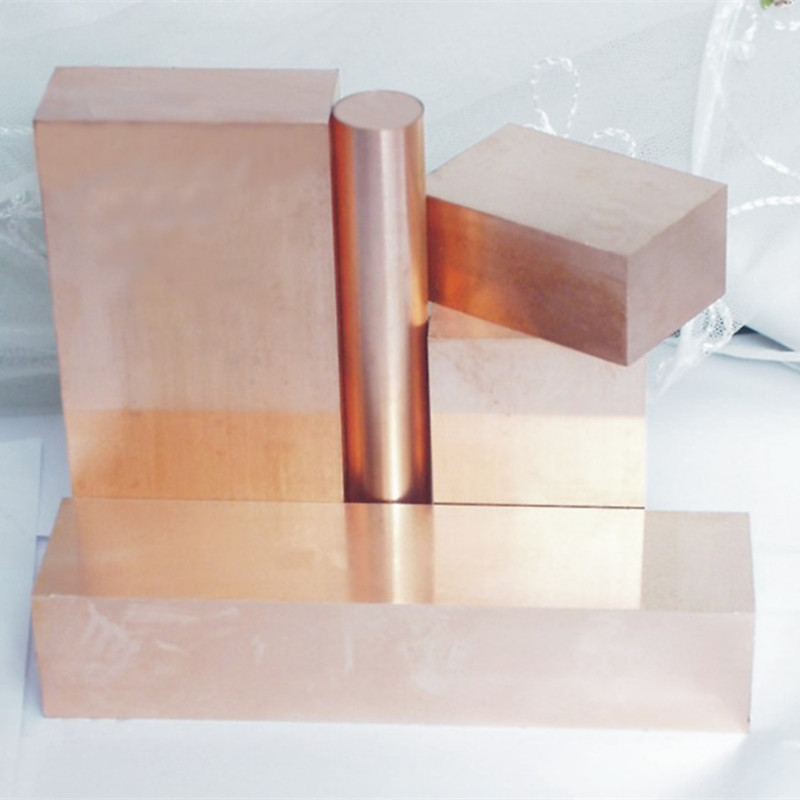

Tungsten Copper Alloy (WCu Alloy)

Tsanangudzo Uye Zvinotsanangurwa

Tsanangudzo:

Tungsten yemhangura alloy inogona kugadzirwa kuita tsvimbo, mahwendefa uye zvimwe zvakagadzirwa zvakasara zvikamu zvinoenderana nezvikumbiro zvevatengi. Inoshandiswa zvakanyanya semagetsi kusangana, maelectrodes, kupisa sinks etc.

Zvinodiwa:

Tungsten Copper Alloy Giredhi:

W50Cu50, W60Cu40, W65Cu35, W70Cu30, W75Cu25, W80Cu20, W85Cu15, W90Cu10.

Kuwanda: 11.8-16.8g/cm3.

Surface: Yakagadzirwa & Ground.

Mhangura Tungsten Tsvimbo: Dia (10-60)mm x (150-250)mm L.

| Kodhi Nha. | Kuumbwa Kwemakemikari% | Mechanical properties | ||||||

| CU | Kusachena≤ | W | Density(g/cm3 )≥ | KuomaHB≥ | RES(μΩ·cm)≤ | ConductivityIACS/ %≥ | TRS/ Mpa≥ | |

| KuW(50) | 50±2.0 | 0.5 | Balance | 11.85 | 115 | 3.2 | 54 | |

| KuW(55) | 45±2.0 | 0.5 | Balance | 12.30 | 125 | 3.5 | 49 | |

| KuW(60) | 40±2.0 | 0.5 | Balance | 12.75 | 140 | 3.7 | 47 | |

| KuW(65) | 35±2.0 | 0.5 | Balance | 13.30 | 155 | 3.9 | 44 | |

| CuW(70) | 30±2.0 | 0.5 | Balance | 13.80 | 175 | 4.1 | 42 | 790 |

| CuW(75) | 25±2.0 | 0.5 | Balance | 14.50 | 195 | 4.5 | 38 | 885 |

| CuW(80) | 20±2.0 | 0.5 | Balance | 15.15 | 220 | 5.0 | 34 | 980 |

| KuW(85) | 15±2.0 | 0.5 | Balance | 15.90 | 240 | 5.7 | 30 | 1080 |

| KuW(90) | 10±2.0 | 0.5 | Balance | 16.75 | 260 | 6.5 | 27 | 1160 |

Copper Tungsten Alloy Advantages

1. Kupisa kuri nani;

2. Zvirinani ablate-resistant;

3. Kusimba kwepamusoro.

4. High density;

5. Excellent thermal uye magetsi conductivity;

6. Zviri nyore kugadzirwa.

Kushandiswa kweTungsten Copper Alloy

Tungsten mhangura (Cu-W) alloy ndiyo inoumbwa netungsten nemhangura iyo inova yake yakanakisa kuita tungsten nemhangura. Inoshandiswa zvakanyanya mumaindasitiri akadai seinjini, simba remagetsi, erekitironi, simbi, spaceflight uye ndege.

1) Arcing contacts uye vacuum contacts mune yakakwirira uye yepakati voltage breakers kana vacuum interrupters

2) Electrodes mumagetsi spark erosion yekucheka michina

3) Kupisa kunonyura senge kutonhora kusingaite zvinhu zvemagetsi

4) Electrodes for Resistance Welding.