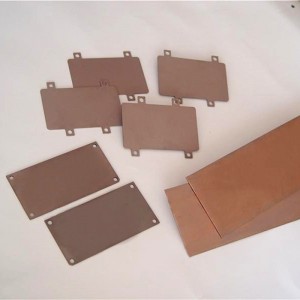

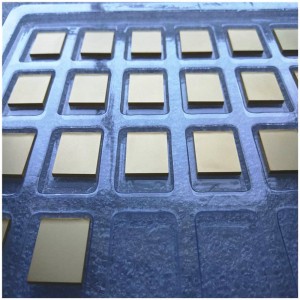

Tungsten Copper WCu Heat Sink

Tsanangudzo

Tungsten mhangura yemagetsi yekurongedza zvinhu ine zvese zvakaderera zvekuwedzera zvivakwa zve tungsten uye yakakwira yekupisa conductivity zvimiro zvemhangura. Chinonyanya kukosha ndechokuti kupisa kwaro kuwedzera coefficient uye kupisa conductivity kunogona kugadzirwa nekugadzirisa kuumbwa kwezvinhu zvakaunza kurerukirwa kukuru.

FOTMA inoshandisa yakakwirira-kuchena uye yemhando yepamusoro mbizha, uye inowana WCu yemagetsi yekurongedza zvinhu uye kupisa singi zvinhu zvine mashandiro akanaka mushure mekutsikirira, kupisa-kupisa sintering uye kupinda mukati.

Zvakanakira Tungsten Copper (WCu) Electronic Packaging Materials

1. Iyo tungsten mhangura yemagetsi packaging zvinhu ine inogadziriswa thermal yekuwedzera coefficient, iyo inogona kufananidzwa neyakasiyana substrates (yakadai se: Stainless steel, valve alloy, silicon, gallium arsenide, gallium nitride, aluminium oxide, nezvimwewo);

2. Hapana sintering activation zvinhu zvinowedzerwa kuchengetedza yakanaka yekupisa conductivity;

3. Low porosity uye yakanaka mhepo tightness;

4. Kutonga kwakanaka kwehukuru, kupera kwepamusoro uye flatness.

5. Ipa pepa, zvikamu zvakaumbwa, zvakare zvinogona kusangana nezvinodiwa zve electroplating.

Copper Tungsten Heat Sink Properties

| Material Giredhi | Tungsten Content Wt% | Density g/cm3 | Thermal Kuwedzera × 10-6CTE (20℃) | Thermal Conductivity W/ (M·K) |

| 90WCu | 90±2% | 17.0 | 6.5 | 180 (25℃) /176 (100℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25℃)/ 183 (100℃) |

| 80WCu | 80±2% | 15.65 | 8.3 | 200 (25℃) / 197 (100℃) |

| 75WCu | 75±2% | 14.9 | 9.0 | 230 (25℃) / 220 (100℃) |

| 50WCu | 50±2% | 12.2 | 12.5 | 340 (25℃) / 310 (100℃) |

Kushandiswa kweTungsten Copper Heat Sinks

Zvishandiso zvakakodzera kurongedza nemidziyo ine simba repamusoro, senge substrates, yakaderera electrode, nezvimwewo; mapuranga anotungamira epamusoro-soro; thermal control boards uye marayadhiya emauto uye evagari vemauto ekudzora kupisa.