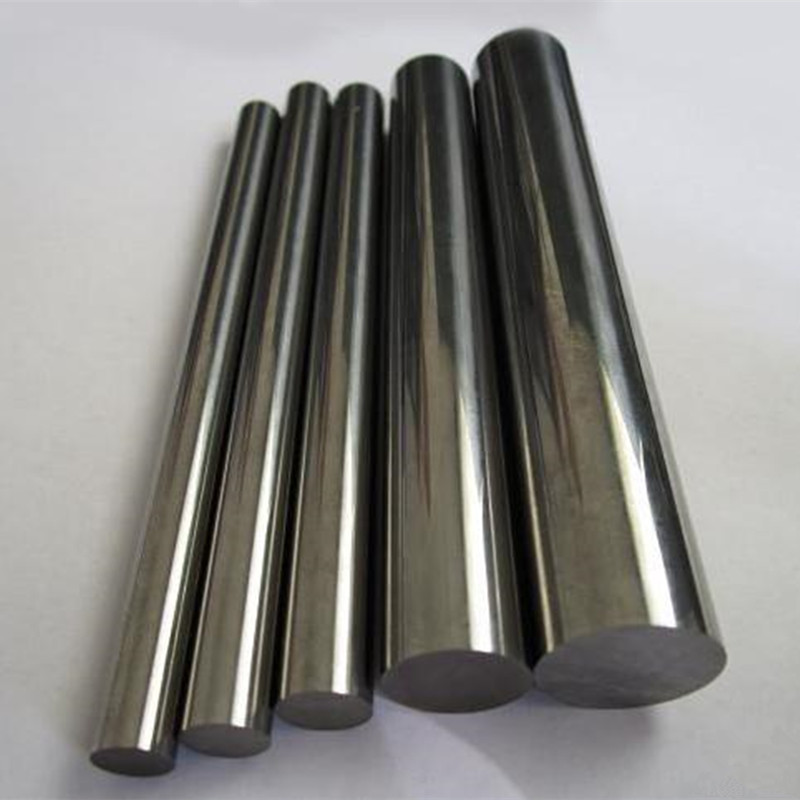

Tungsten Heavy Alloy Rod

Zvinotsanangurwa

Tungsten Heavy Alloy Giredhi:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (Slightly Magnetic).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (Nonmagnetic).

Density:16.8-18.8g/cm3.

Surface:Machined & Ground.

Standard:ASTM B777.

Diameter:5.0mm - 80mm.

Urefu:50mm - 350mm.

Tungsten Yakakwira Density Alloy Advantages

High density (kusvika 65% denser pane Lead).

Denser zvinhu zviripo (yakachena Tungsten, Goridhe, platinamu boka simbi) asi kushandiswa kwavo kunorambidzwa nekuwanikwa, kushanda uye mutengo.

Kupa misa iyo nzvimbo yevhoriyamu ishoma.

Huremu hwakadzama hwakakosha panodiwa chokwadi pakuiswa kwehuremu.

Kuiswa kwehuremu mumamiriro ezvinhu apo kubuda kwemhepo kune simba guru.

Thermal Properties yeTungsten Heavy Alloys

High softening tembiricha.

Low thermal conductivity uye yakaderera coefficient yekuwedzera inopa zvinhu zvakanyanya kupikisa kuneta kwekupisa.

Yakanakisa solder erosion kuramba kune yakanyungudutswa aluminium.Yakasimba pakupisa kwepamusoro nekugadzikana kwekushisa kwepamusoro.

Tungsten Yakakwira Density Alloy Mechanical Properties

● High Young's modulus ye elasticity.Haikwekwe kana ikasangana nemasimba akakosha, kusiyana neLead.

● Pasinei nesimba radzo, rinoramba riri ductile uye risingagone kutsemuka.

● Kuoma kwakaoma kwema alloys kunowanzoita 20-35 Kuoma HRC.

Yakakwira-Density Tungsten Yakavakirwa Alloy

| Alloy Type(%) | HD17 90W 6Ni 4Cu | HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Balance Ni, Fe, Mo | HD17.7 93W Chiyero Ni, Fe, Mo | HD18 95W 3.5Ni 1.5Cu | HD18D 95W 3.5Ni 1.5Fe | HD18.5 97W 2.1Ni .9Fe |

| MIL-T-21014 | Kirasi 1 | Kirasi 1 | Kirasi 1 | - | - | Kirasi 3 | Kirasi 3 | Kirasi 4 |

| SAE-AMS-T-21014 | Kirasi 1 | Kirasi 1 | Kirasi 2 | - | - | Kirasi 3 | Kirasi 3 | Kirasi 4 |

| AMS 7725 C | 7725 C | 7725 C | -- | -- | -- | -- | -- | -- |

| ASTM B777-87 | Kirasi 1 | Kirasi 1 | Kirasi 2 | - | - | Kirasi 3 | Kirasi 3 | Kirasi 4 |

| Typical Density(g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Typical Density(lbs/in3) | 0.614 | 0.614 | 0.632 | 0.636 | 0.639 | 0.65 | 0.65 | 0.668 |

| Typical Hardness RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ultimate Tensile Simba Min(ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% Offset Goho Simba Min(ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Minimum % Elongation(1" kureba kwegeji) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Proportional Elastic Limit(PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Modulus yeElasticity(x106psi) | 40 x 106 | 45 x 106 | 47 x 106 | 52 x 106 | 53 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x10-6/0C(20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| Thermal Conductivity(CGS Units) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity(% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Magnetic | No | Zvishoma | Zvishoma | Zvishoma | Zvishoma | No | Zvishoma | Zvishoma |